WHAT AN AFM DOES:

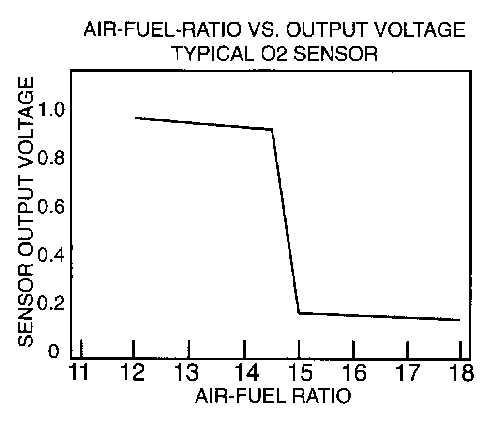

The AFM measures air velocity into the throttle body and sends a corresponding

voltage to the Engine Computer/Controller Unit (ECU). The ECU then calculates how much fuel to mix

with the volume of air. If the AFM is falsely reporting too much or too

little air, then the ECU mixes the incorrect amount of fuel and the car

runs too lean or too rich.

WHAT AN AFM DOES WHEN SET UP INCORRECTLY:

Too Much Fuel (Rich Mixture) results in poor mpg, sooty/carbon plugs and

exhaust pipe, black smoke, and back firing. All of this can damage

head/valves/exhaust.

To Little Fuel (Lean Mixture)

results in good gas mileage but hotter engine

and pre-ignition in the intake "front fire". This can damage

engine and also AFM flap and Throttle Body from the front fire burst and heat. White

spark plug insulators with spattered electrode erosion/melting

is a sign of lean

fuel mixture.

HOW IT WORKS:

The AFM is a potentiometer (like a volume knob on a stereo) that is turned by a wind vane "flap".

The flap is in the air path between the air filter and throttle body. As

more air is sucked into the engine, the more the AFM flap gets pushed by the moving

air. This in turn, rotates the potentiometer wiper. A voltage from this

wiper is sent to the ECU. The ECU then adds fuel proportionate to this

voltage. When the car is idling, the air flow is low so the flap is nearly

closed and the voltage is low thus the ECU sends little fuel. When the car

is accelerating, the air flow is great so the AFM flap is pushed wide open

and the voltage is high so the ECU sends lots of fuel to the engine.

The AFM also has an air temperature sensor that is read by the ECU. The

amount of oxygen in the air is proportionate to the density which is

proportionate to the temperature. The ECU adds more fuel when the air is

colder and denser to maintain the correct ratio of fuel to oxygen. The ratios of air to fuel are commonly set between

12:1 and 15:1. Note: the ECU only adds extra fuel when the incoming air

temperature is 20°C (70°F) or less.

A safety switch is also included in some 280z AFM's (75 to early 77 click

here to learn more about fuel cut off) . When the engine is stopped,

the flap is closed. A switch senses that the flap is closed and turns off

the fuel pump. The primary function of this feature is to prevent fuel

being pumped when a car crashes. Note: some 280z's have a second wire from

the oil pressure sensor that controls fuel cut off in place of the AFM

switch.

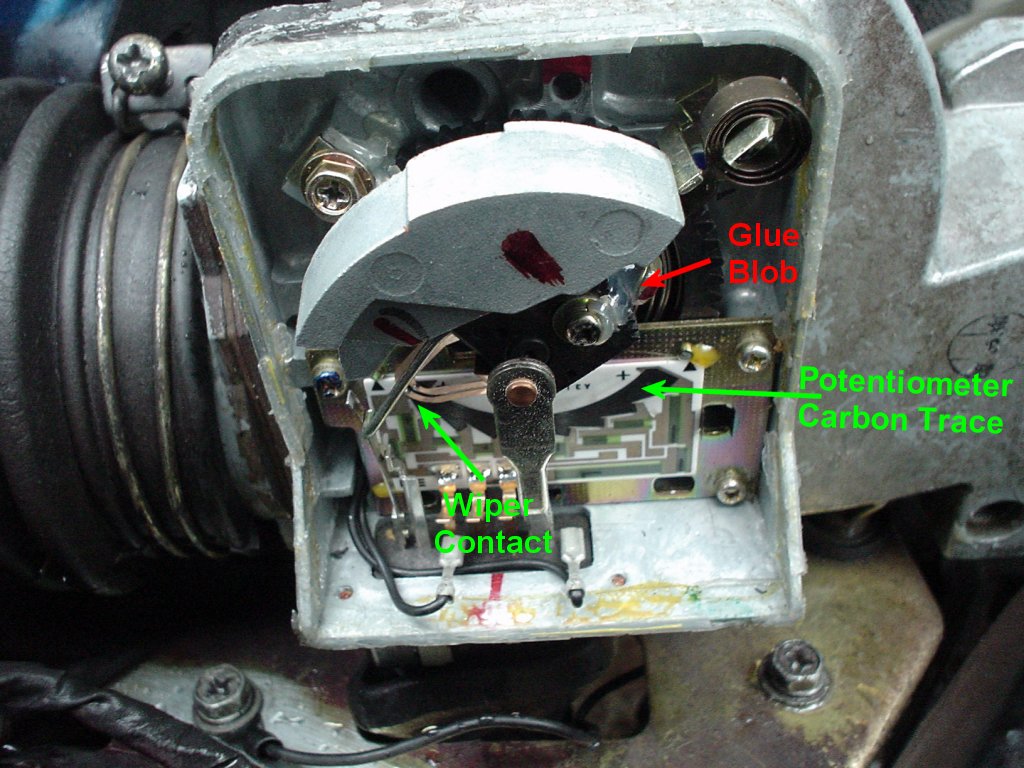

Picture 1

FEATURES IN Picture 1:

The big grey chuck of metal is a counter balance weight. It is used to offset the

weight of the wind vane "flap" in the air path to allow for easy

rotation by low air flow..

The "Return to Zero Shock Absorber" is simply spring metal that

absorbs the shock of the rotating Counterweight and Flap when the air flow

stops. It prevents the AFM from beating itself to death every time the

engine is stopped.

The Black Wheel and Coil Spring is the mechanism that controls how far the

flap opens when air flows through the throttle body. This is the heart of

the AFM and if the spring is set incorrectly, the related voltage to the

ECU will be wrong and it will send too much or too little fuel. If the

spring is wound too tight, the AFM's flap will not move enough and the ECU

will not send enough fuel thus a lean mixture will occur. If the spring is

wound too loose, the AFM's flap will move too much and the ECU will send

too much fuel thus a rich mixture will occur.

IT IS IMPORTANT TO POINT OUT THAT THE BLACK WHEEL IS UNDER TENSION AND

THAT REMOVING THE LOCKING SCREW WILL RESULT IN IT GOING "SPRONG"

and RECOILING.

BE SURE TO MARK A TOOTH PRIOR TO TOUCHING THE LOCKING SCREW!!!! Besides I

have not got to that step yet so hands off!! :)

You will also notice a blob of silicone or glue. If this is broken, you

can immediately determine that the AFM was "messed with". Upon

inspection of my 77z, the

previous owner had obviously turned the black wheel about 10 tooth-steps

to the lean side as a smaller part of the blob had been separated and was

~ 10 teeth to the right.

Please note the reference mark that I scribed into the black wheel. It is

impossible to see but there is a corresponding scribe mark in the cast

metal body as well. (It is good to have both wheel and body scribed in the

same location. Preferably at the centre of a tooth.

Idle Flow Adjust

This allows you to tweak the position of the AFM flap at idle thus you can

control the rich/lean mixture. This adjustment controls the air flowing

around the flap in a "bypass" passage under the AFM's main

passage. It works in a similar fashion to the idle set screw in the

throttle body.

Click to read an

interesting Air to fuel Ratio Blurb by Ian Staunton

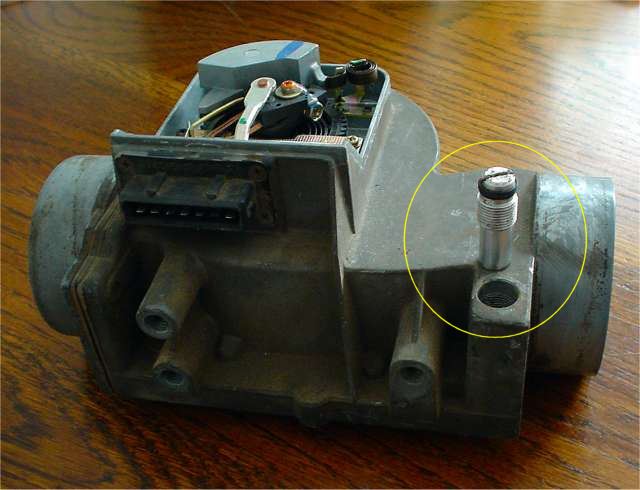

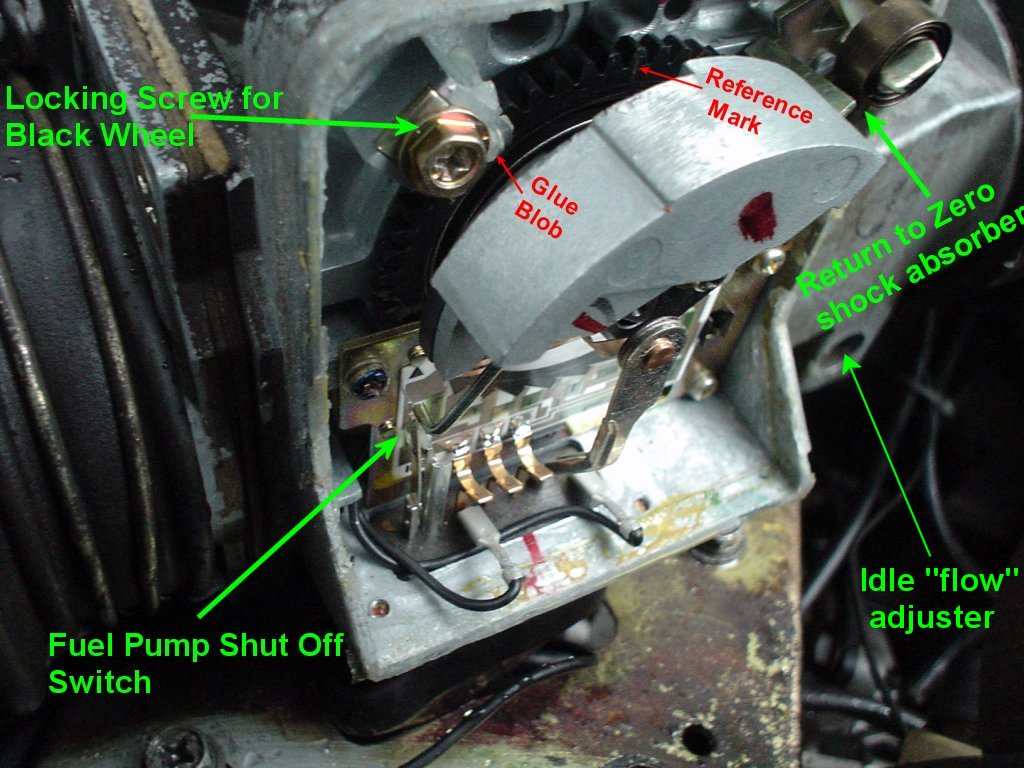

AFM Parts (more)

Here you can see a few more features/parts and some of the previous parts in more detail.

Potentiometer Wiper. It contacts the carbon trace and sweeps a path along it as the flap is moved. It "sends" the corresponding voltage that it "picks up" from the carbon trace".

Carbon Trace. This is the resistive element that divides the voltage. As the wiper travels along it, the corresponding voltage is picked up from approximately 2V to 7V. it is interesting to note that the ECU also measures the resistance across a "reference' resistor in the AFM. Since resistance changes with temperature, any resistance changes in the primary carbon trace can be compensated for by the same amount measured in the reference resistor.

Glue Blob #2. The related locking screw allows you to set the wiper to the 0V position when the flap is closed. It also allows you to adjust the Fuel Pump Cut-Off Switch actuator (silver nail-like arm).

With the AFM in the off position, the "Return to Zero" shock absorber spring should be resting against the rotating weight assembly. (Mine was bent back and not touching... possibly from age or from an explosive "front fire" that slammed the AFM flap shut from behind... anyway I simply bent it back into place. When the Assembly Returns to Zero, the spring metal shock absorber contacts ~ 1/2 cm before the assembly hits the stop.

Inspection Time:

Remove the AFM from the car (remove the two rubber hoses.. careful not to rip/stress and the four bolts on the bottom plate... note the ground strap...also DISCONNECT THE BATTERY -NEG terminal and unplug the connector to the ECU )

With the AFM on your lap, verify that the return to zero shock absorber is doing it's job. If not, do the obvious to "make it so" said Picard. Gently bending the metal is all that may be needed (look at the next slide to see how the shock absorber should be set up).

Inspect the Flap and make sure it moves freely. Check for damage, tight spots, and play.

Inspect the Fuel cut off switch and ensure the contacts are physically making and breaking when the AFM is in the "off" mode.

Inspect the wiper and ensure it is contacting the trace at the most clockwise (CW) end. Actually it should stop about 2 to 4 mm from the end of the carbon trace and not run off it)

(My AFM had the wiper shooting too far CW and it was off the trace and registering "open" on a volt meter. I had to loosen the second locking screw near the centre of the assembly (not the black wheel one but rather the "black arc/pie" one and move the wiper as well as the silver arm that activates the fuel pump shutoff switch... play with it gently and you can figure it out)

Also inspect the wiper to carbon trace contact point as the wiper is swept along the trace (move the flap to make it travel)

CLEANING TIME:

Use a good quality switch/contact cleaner such as Caig "Deoxit"

Clean the Fuel Pump Switch Contacts

Clean the wiper and carbon trace

Clean the multi-pin conductor contacts

MEASUREMENT TIME!!

Now for some multimeter measurements at the connector.

Measure the resistance across the Fuel Shut off Switch (Pins 39 and 36). Move the AFM flap and ensure the resistance is infinite when the flap is closed and quickly changes to 0 ohms when the flap starts to open.

Measure the resistance from the high side to the low side of the pot/copper trace. (Pins 8 and 6). It should read ~180ohm

Measure the resistance across the "standard"/"Reference"/"Control" resistor. (Pins 8 and 9). It should read 100ohms

Measure the resistance across pins 7 and 8 while moving the flap. It should change. (though it may be jumpy)

Repeat this but between pins 6 and 7 while moving the flap.

Measure the resistance of the thermal sensor. It should read 2500ohms +/-250ohms@ 68°C

![afm[1].gif (132536 bytes)](afm1_small.gif)